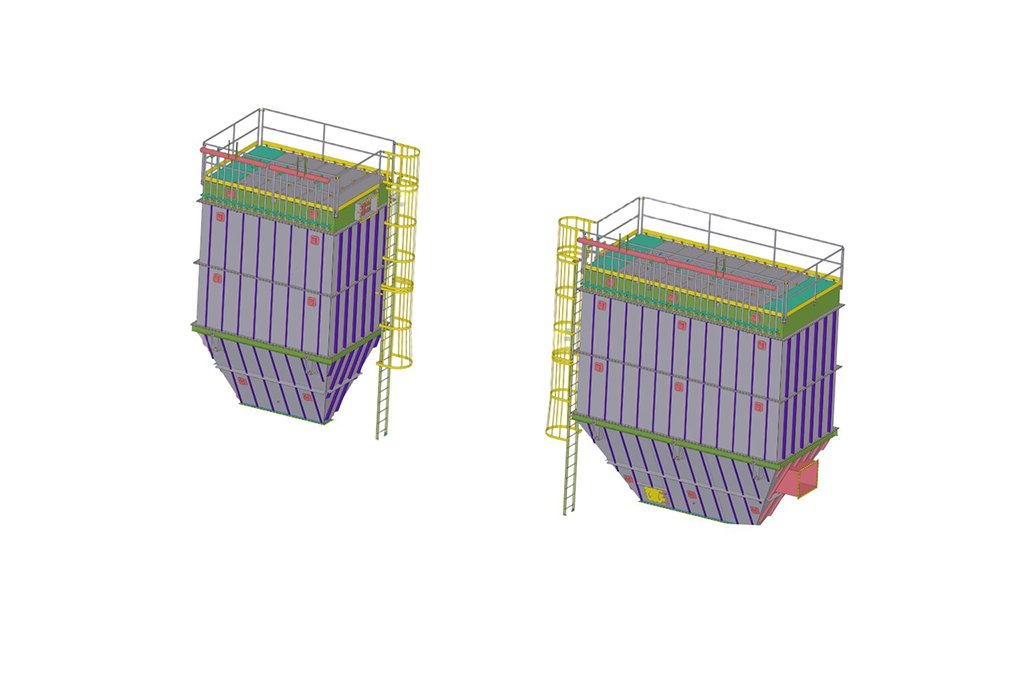

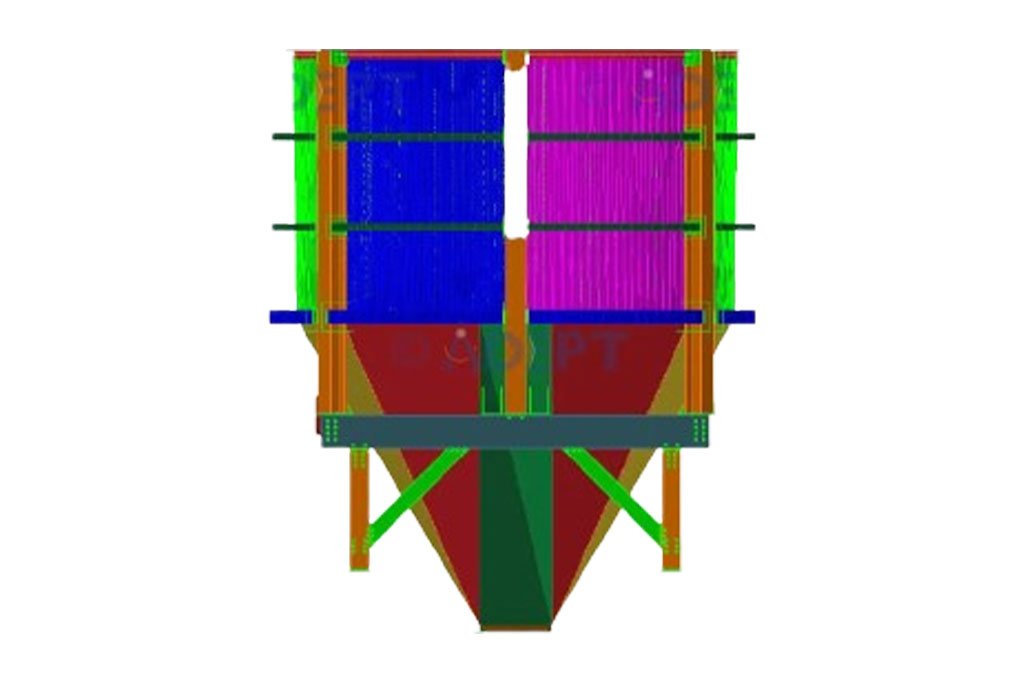

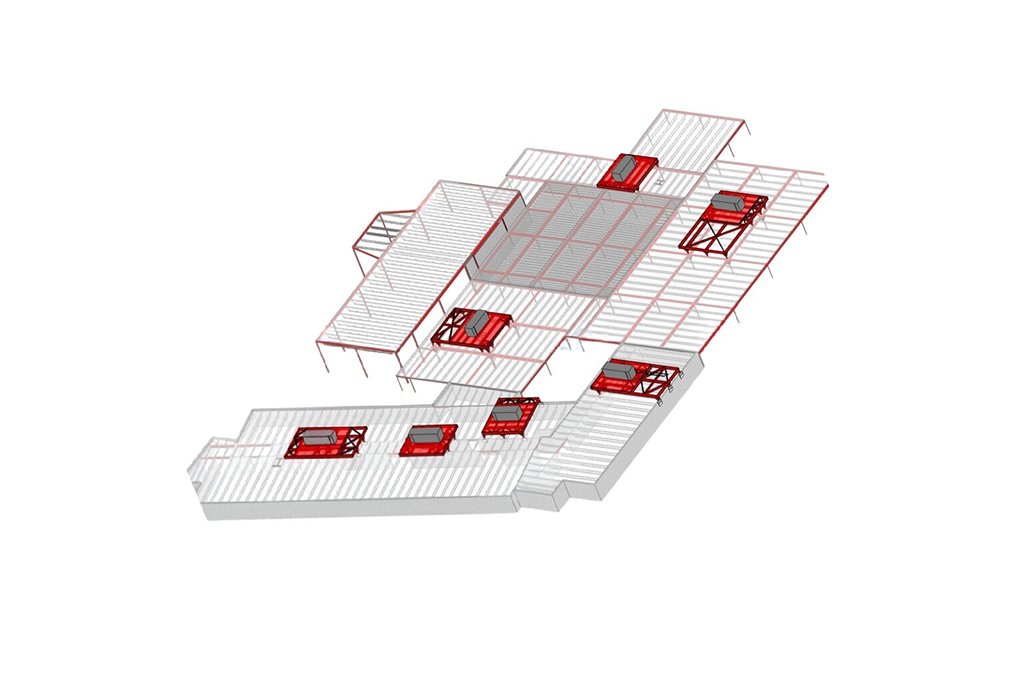

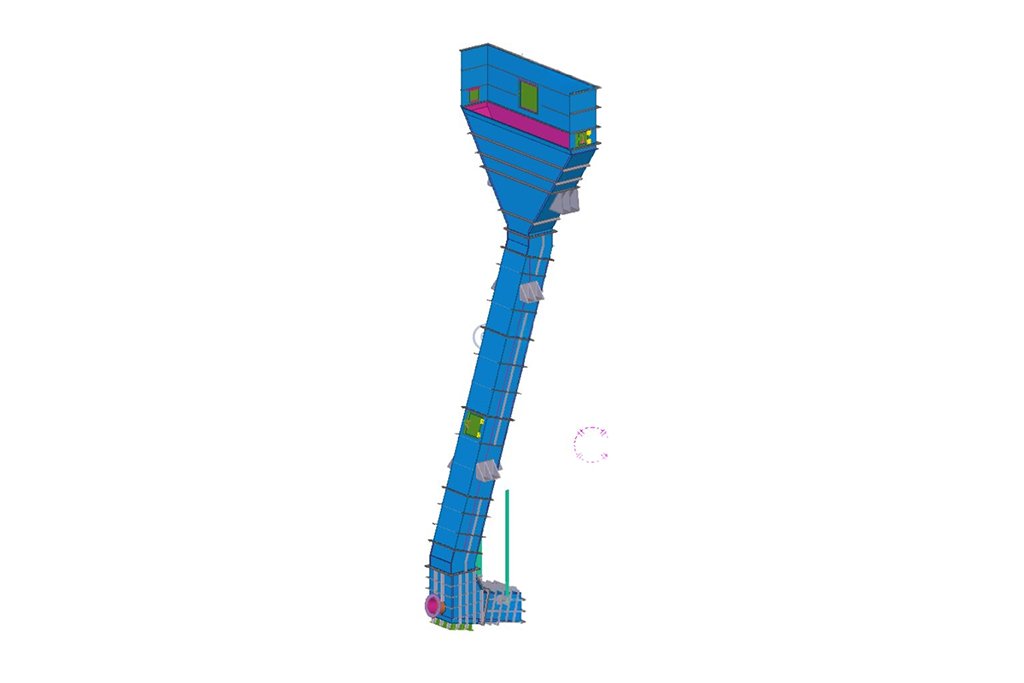

Adept Engineering Solutions Pvt Ltd, based in Namakkal, Tamil Nadu, stands out as a premier 3D modeling & detailing company in Gujarat, delivering fabrication‑ready structural steel models and drawings for global fabricators since 2013. Our blend of advanced software tools—Tekla Structures, SDS2, Advance Steel—paired with strict AISC and ISO‑9001:2015 compliance, positions us as your trusted partner for high‑intention fabrication projects

- Global Certification & Standards

ISO‑9001:2015 quality system, AISC and NISD standards ensure reliable, code‑compliant deliverables. - Cutting‑Edge 3D Modeling Technologies

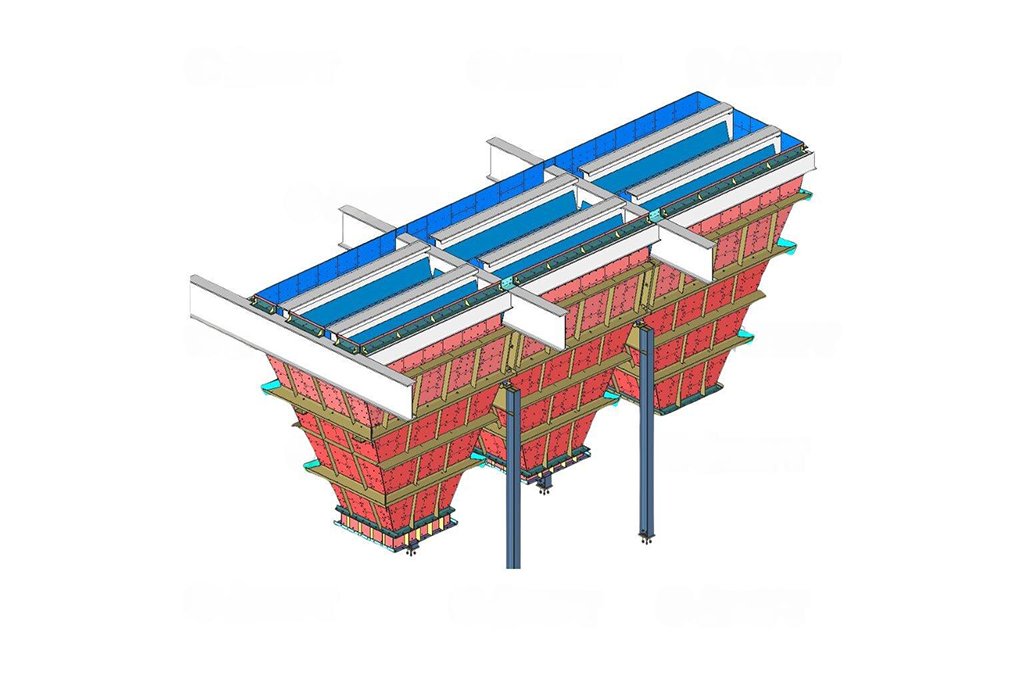

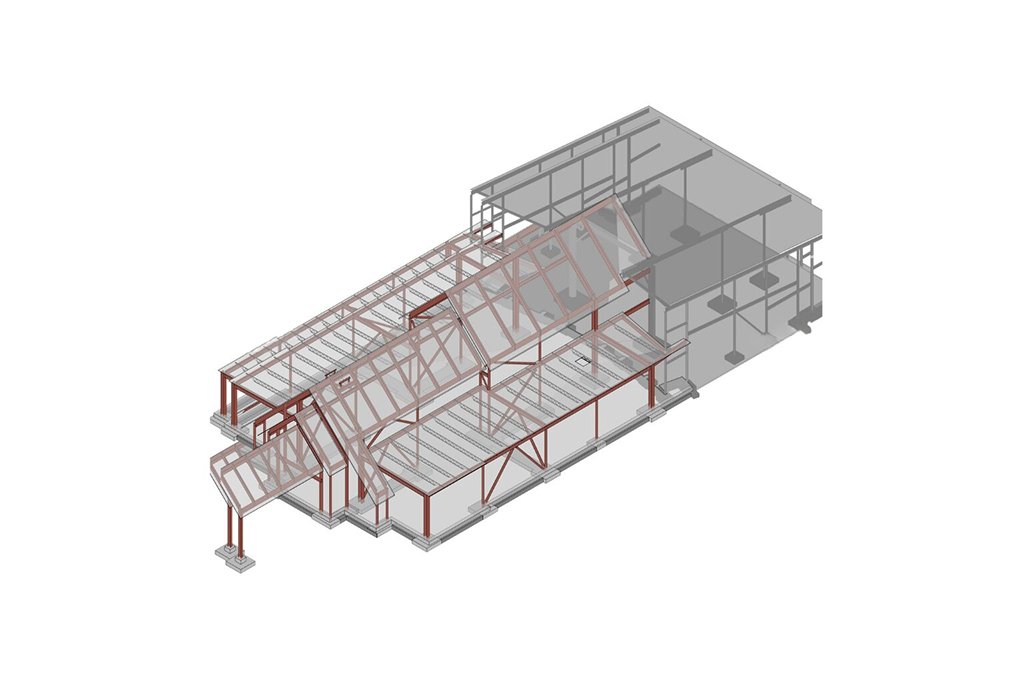

Proficiency in Tekla, SDS2, Advance Steel enables precision BIM models, clash‑free coordination, and CAD‑ready shop drawings - Skilled Engineering Workforce

A talented team of 50+ engineers and detailers delivering efficient, error‑free models tailored to US/India fabrication requirements - Seamless Communication Workflow

Dedicated project managers, daily progress updates, and timezone‑friendly coordination for fabricators in the USA. - Comprehensive Deliverables

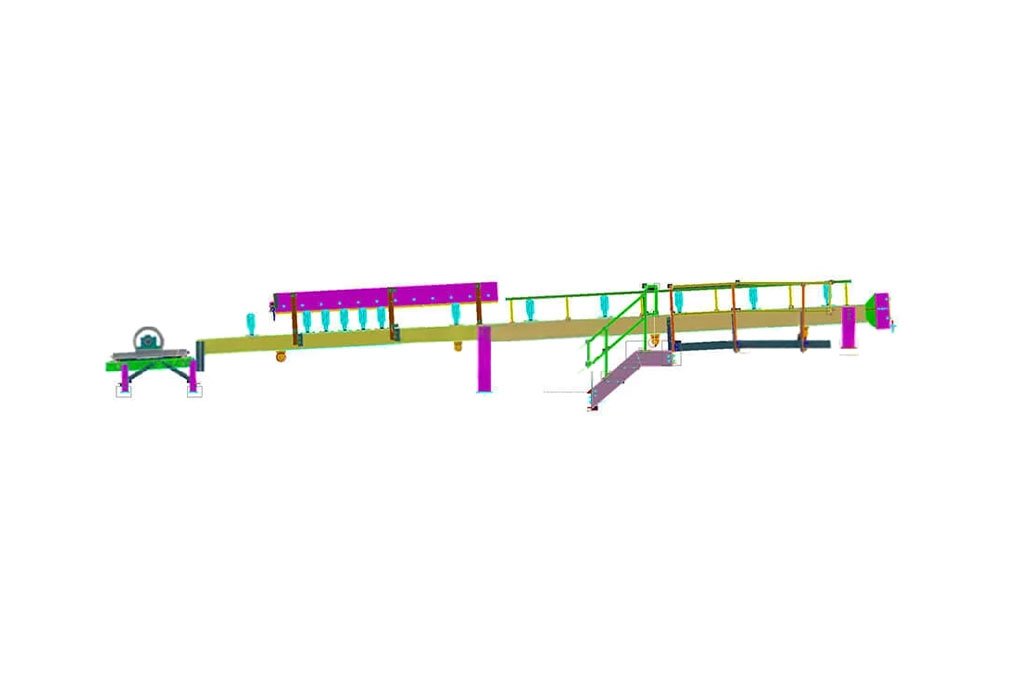

Full-suite output—3D models, fabrication drawings, CNC files, BOQs, erection plans—ready for immediate production.

BIM‑Driven 3D Modeling |

Shop & Erection Drawings |

Connection Design & Detailing |

Quantitative Take‑Off & BOM |

BIM Coordination & Clash Resolution |

Fabricator‑Friendly Outputs |

Intelligent 3D structural models using Tekla, Advance Steel, or SDS2, perfect for clash detection and coordination. |

High‑precision, fabrication‑ready drawings (shop plans, erection views, connection sketches). |

AISC‑compliant connection design complete with moment connections, shear tabs, gussets, and custom detailing |

Accurate bills of material and CNC‑ready output for fabrication and procurement. |

Proactive clash management ensuring seamless integration with MEP and architectural models. |

CNC files, Fabsuite/FabTrol reports, anchor‑bolt layouts customized for USA/India workshops. |

- Boosted Productivity — Automated detailing cuts production time by up to 40%.

- Fabrication Accuracy — Eliminates field errors with shop‑level precision.

- Reduced RFIs — Pre‑defined reactions and load parameters speed up detailing.

- Cost Efficiency — Optimized modeling reduces material waste and revision overheads.

- Global Compliance — Conformity to international standards for US and Indian fabrications.

- Case studies: Complex steel factories, bridges, commercial structures across India and the USA

- Software stack: Tekla Structures, SDS2, Advance Steel, RAM Connections, Bluebeam, Idea Statica, FabSuite.